|

|

雷射道路影像檢測系統

Laser Road Image System, LRIS |

|

|

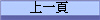

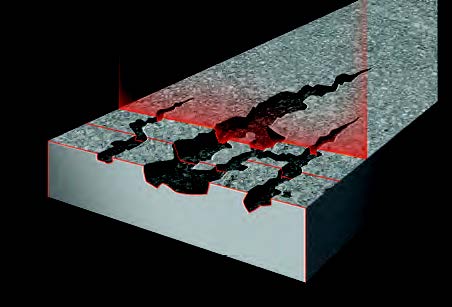

PAVEMETRICS’s laser road imaging

system (LRIS) is composed of

two high resolution linescan

cameras andlasers that are

configured to image 4m

transverse road sections with 1

mm resolution at speeds that can

reach 100 km/h. This patented

imaging system was,designed to

increase the contrast and

visibility of both small

longitudinal and lateral road

cracks.

The LRIS optical configuration

increases the visibility of even

the smallest cracks by using the

incident illumination angle of

the laser to cause the cracks to

project shadows.

Using high power laser line

projectors and advanced optics,

the LRIS system is very robust

to variations in outside

lighting conditions and shadows

cast by roadside objects,

viaducts and the inspection

vehicle itself. |

|

KEY FEATURES

specificat ions

-

Image size: 4096 pixels/line

-

Line rate: 28000 lines/s

-

Image width: 4 m (3950 mm

nominal)

-

Laser class: 3B

-

Power: 250W at 120/240 VAC

-

Sensor size (approx.): 300

mm(H) x 375 mm(L) x 200 mm(D)

-

Sensor weight (approx.): 20

kg

|

|

|

|

|

|

|

|

|

雷射道路路轍量測系統

Laser Rut

Measurement System, LRMS |

|

|

Pavemetrics’s laser rut

measurement system (LRMS)

is a transverse profiling device

that detects and characterizes

pavement rutting. The LRMS can

acquire full 4-meter width

profiles of a highway lane at

normal traffic speeds, with 2

options of maximum sampling

rate: 30 or 150 Hz. The system

uses two 3D laser profilers that

digitize transverse sections of

the pavement with 1280 points.

Custom optics and high-power

pulsed laser line projectors

allow the system to operate in

full daylight or in night-time

conditions. Road transverse

profile data can be collected

and processed in real time on

board the vehicle. Rut

extraction algorithms have been

developed to automatically

measure rut depth and width.

The system is delivered with a

complete DLL library of C/C++

functions allowing the user to

easily configure the sensors,

acquire transverse profiles,

extract road rut data, classify

rut type (short, multiple, long

radius) and validate the laser

profiler calibration. Over the

past years, this system has been

used on a continuous basis by

dozens of governments and

private agencies. Hundreds of

thousands of road kilometers

have been surveyed using this

technology. |

|

|

|

KEY FEATURES

-

1280 point 3D transverse

profiles

-

Daylight or nighttime

operation

-

Short integration times for

minimal image blur at

maximum inspection speeds

-

A library of C/C++ functions

for easy use and integration

-

Proven performance

-

Inspection speeds up to 100

km/h

-

Rut depth and type (short,

multiple and long radius) is

evaluated.

BENEFITS

-

Immediate and precise

detection and

characterization

-

of rutting conditions

-

Optimization of road

maintenance funds

-

Improvement of safety due to

better road

-

pavement maintenance

|

SYSTEM

SPECIFICATIONS

-

Number of laser profiles: 2

-

Number of 3D points per

profile (max): 1280 points

-

Sampling rate: 30 or 150

profiles/s

-

Vehicle speed: 0 to 100 km/h

-

Profile spacing: adjustable

-

Transversal field-of-view

(nominal): 4 m

-

Transversal resolution

±2

mm

-

Depth range of operation:

500 mm (30 Hz)or 450 mm (150

Hz)

-

Depth

accuracy (nominal) ±1

mm

-

Laser profiler dimensions

(approx.):

108 mm(W) x 692 mm(H) x 220

mm(D)

-

Laser profiler weight

(approx.): 12 kg

-

Power consumption (max): 150

W at 120/240 VAC

|

|

|

|

|

|

|

|

|

雷射道路裂縫量測系統

Laser

Crack Measurement System, LCMS

|

|

|

The laser

crack measurement system (LCMS)

uses laser line projectors, high

speed cameras and advanced

optics to acquire high

resolution 3D profiles of the

road. This unique 3D vision

technology allows for automatic

pavement condition assessment of

asphalt, porous asphalt,

chipseal and concrete surfaces.

The LCMS acquires both 3D and 2D

image data of the road surface

with 1 mm resolution over a 4 m

lane width at survey speeds up

to 100 km/h.

LCMS data is acquired and

compressed in real time in the

survey vehicle so as to minimize

storage needs (<1Gb per km). The

collected data can then be

analyzed using Pavemetric’s

data processing toolbox (DLL

library of C/C++ functions).

This library has functions to

detect and analyze cracks, lane

markings, potholes, ravelling,

and macro-texture. Rutting is

also measured and characterized

using more than 4 000 points and

rut depth and type (short,

multiple, long radius) is

evaluated.

Concrete road surfaces can be

scanned to evaluate joints,

tinning and faulting between the

concrete slabs.IMUs can be added

to the sensors in order to

measure longitudinal profiles,

IRI, slope and crossfall. |

.jpg) |

KEY FEATURES

-

Automatic crack detection

and severity

-

4 160 point rutting (rut

depth, rut type)

-

Macro-texture measurements

over 100 % of the lane

width.

-

3D and 2D data to

characterise: cracks, pot

holes, ravelling, sealed

cracks, joints in concrete,

tinning, etc.

-

Day and night operation

-

Low power consumption

-

High resolution (1mm)

downward images

-

IRI and longitudinal profile

-

Slope and crossfall

SYSTEM

SPECIFICATIONS

-

Number

of laser profiles : 2

-

Sampling rate : 5 600

profiles/s or 11 200

profiles/s

-

Vehicle speed : 0 to 100

km/h

-

Profile spacing : 1 to 5 mm

(adjustable)

-

Transversal field of view :

4 m

-

Transversal accuracy : 1 mm

-

Transversal resolution : 4

096 points/profile

-

Depth range of operation :

250 mm (adjustable)

-

Depth accuracy : 0.5 mm

-

Laser profiler dimensions :

428 mm (h) x 265 mm (l) x

139 mm (w)

-

Weight : 10 kg

-

Power consumption (max) :

150W at 120/240 VAC

|

|

|

|

|

|

|

|

|

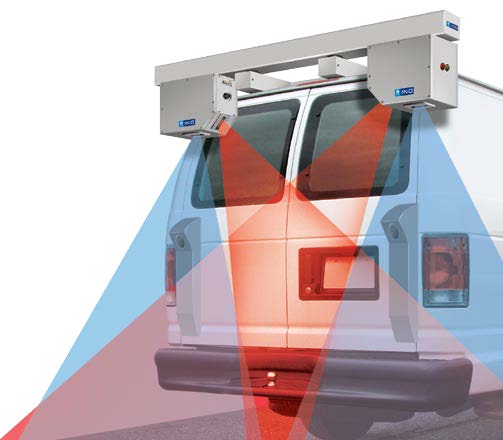

雷射跑道鋪面異物偵測系統

Laser

Foreign Object Debris Detection System,

LFOD |

|

|

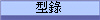

The laser

foreign object debris (LFOD)

detection system uses high speed

cameras, custom optics and laser

line projectors to acquire both

2D images and high resolution 3D

profiles of airport runways,

taxiways and aprons in order to

automatically detect even the

smallest objects at highway

speeds.

The LFOD system can be operated

both during daytime and

nighttime as well as under all

types of lighting conditions.

Sun and shadows as well as

various pavement types ranging

from dark asphalt to concrete

can be scanned at inspection

speeds from 0 to 100km/h.

Depending on the configuration

selected, an entire runway can

be scanned in only a few

minutes; automatically detecting

FOD as small as 2 mm in size.

FOD and GPS data is collected

simultaneously and is analysed

in real-time. Alarms can be

pre-set to trigger upon

detection of FOD of specific

sizes or volume. Included

software reports size, number

and location data for each of

the detected debris; thus

allowing operations and

maintenance personnel to quickly

decide whether to remove

individual threats or to proceed

with a general runway

maintenance program. |

|

KEY FEATURES

-

Detection of FOD as small as

2mm

-

24 hour operation; day and

night-time

-

Automated detection; alarms

can be pre-set to trigger

upon the detection of

specific FOD sizes

-

Safe and efficient;

operational speeds from 0 to

100 km/h

-

Flexible configuration;

scanning width of 12 m-18 m

per pass.

-

Cost-effective installation;

typically can be mounted on

existing inspection

equipment

-

Accurate; GPS tagging of

detected debris

SYSTEM

SPECIFICATIONS

-

Number of laser profiles : 4

or 6 sensors

-

Sampling rate : 11,200

profiles/s

-

Transversal field of view :

12-16 m

-

Transversal resolution : 1.5

mm

-

Vertical accuracy : 1 mm

-

Laser profiler dimensions :

428 mm (h) x 265 mm (l) x

139 mm (w)

-

Weight : 10 kg

-

Power consumption (max):

300W at 120/240 VAC

|

|

|

|

|

|

|

|

雷射隧道斷面掃瞄儀

Laser Tunnel

Scanning System, LTSS |

|

|

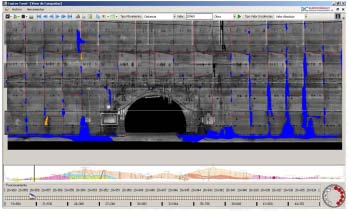

The Laser

Tunnel Scanning System (LTSS)

uses multiple high speed laser

scanners to acquire both 2D

images and high resolution 3D

profiles of tunnel linings.

This system can scan a full

tunnel vault (24m) at 1mm

resolution image and 3D data at

acquisition speeds up to 20km/h.

Once digitized the tunnel data

can be viewed and analyzed

offline by operators using

multi-resolution 3D viewing and

analysis software that allow the

high precision measurement of

virtually any tunnel feature.

Automatic analysis software is

available to detect and rate the

condition of joints, faulting,

cracks, degraded concrete, wet

as well as wet and humid area

tunnel linings.

The LTSS technology was used to

scan high speed TGV rail tunnels

such as the 28km long Spanish

Guadarrama tunnel in full one

millimetre resolution (x,y,z) in

just 3 hours. The system was

also used to acquire data on the

Tokyo Metro System in Japan.

Vaults are scanned one half

going forward and the second

half coming back.

The LTSS is one hundred times

faster and 10 times more

accurate than typical LIDAR

technology. The LTSS can acquire

120,000,000 3D and 2D image

points per second at an accuracy

of 0.5 mm compared to typical

LIDAR accuracies of 5.0 mm for

just a few 100,000 points. The

standard LTSS configuration (6

sensors) allows for the scanning

of a full 12 m of tunnel surface

perimeter in a single pass.

Larger surfaces can be captured

through multiple passes (and the

images and data

“stitched”)

or scanning width can be

increased through the addition

of sensors. |

|

KEY FEATURES

-

Full vault scanning.

-

1mm resolution images and 3D

data.

-

100 times faster and 10

times more accurate than

lidar scanning.

-

Measure tunnel features with

sub millimeter accuracy.

-

Visualize 1mm surface

defects from any point of

view without leaving the

office.

-

Scanning speeds up to

20km/h.

-

Automatic analysis software

of voussoir type tunnels

available.

-

Rail scanning options also

available.

SYSTEM

SPECIFICATIONS

-

Number of laser profiles : 6

sensors (standard)

-

Sampling rate : 5,000

profiles/s

-

Points per profile : 12,000

points (2D and 3D)

-

Total sampling rate :

120,000,000 points/s (2D and

3D)

-

Transversal field of view :

12m

-

Transversal resolution : 1mm

-

Vertical accuracy : 0.5mm

-

Laser profiler dimensions :

428mm (h) x 265mm (l) x

139mm (w)

-

Weight : 10 kg

|

|

|

|

| |

|

|